Liên hệ quảng cáo

Assessment compress strength of high-performance concrete with variable content of nano silica by one-way anova and tukey’s method

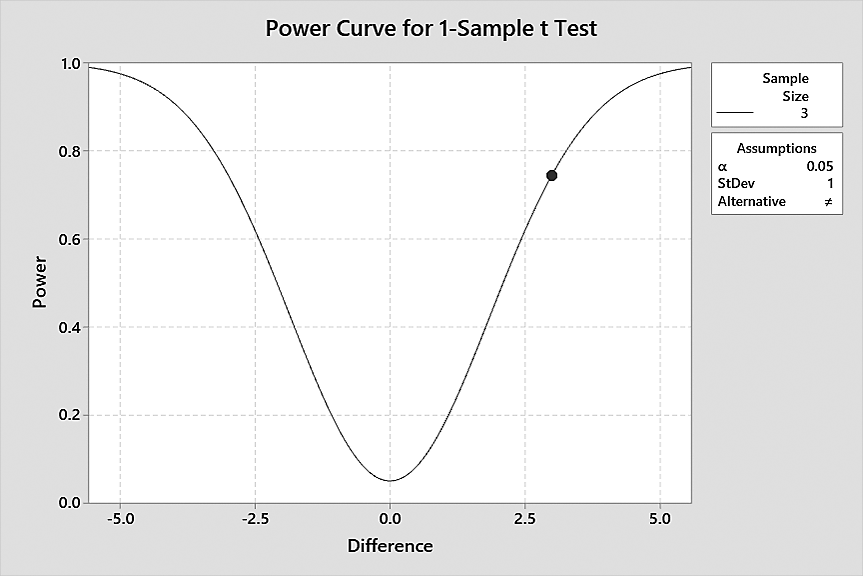

Nano-silica is increasingly proving its features in the manufacture of high-performance concrete. Incorporating nano-silica into the mixture to improve the mechanical properties of concrete has become a field of interest. A very high surface area characterizes ultrafine Nano Silica particles to mass ratio and active ability. In addition to tightening the structure, nano-silica also activates the cement’s increased pozzolan reactions. The pozzolanic reactions help eliminate the unstable components in concrete (calcium hydroxide), producing gel products with better quality than before. Therefore, the experimental results were evaluated by one-factor variance analysis and posthoc analysis by Tukey’s test to clarify further the effect of nano-silica levels with a range of from 0% to 3% of the total weight of adhesive to the compressive strength of high-strength concrete at 28 days of age and results shown that a nano-silica ratio of 1.5% shows the most suitable value by Mininitab19 softwar

Author: Ph.D. Nguyen Thi Thu Nga

University of Transport Technology

Ph.D. Tran Viet Hung

University of Transport and Communications

M.S. Ngo Van Thuc

Mien Tay Construction University

|

| Sample selection analysis for a sample group |

Since the 1980s, high-performance concrete (HPC) has been studied and applied widely in many countries around the world, as the results bringing not only great technical efficiency but also economic efficiency. In almost all types of construction structures, HPC is taken part in because of the quality of products, which is more affordable than conventional concrete considering both structural and longevity. Appear of HPC is a crucial step in the field of construction by made with traditional materials combined with modern additives and additional adhesive materials.

In recent times, with a more in-depth study of nanometer-sized materials and reduced production costs, the use of nano-silica (NS) has received a special attraction in concrete fabrication and HPC. According to Chithra’s research [1], only a small amount of NS is sufficient to improve the properties and durability of HPC. Studies Qing, Dunster, Senf et al. Suggested that adding 1 kg of silica fume would reduce about 4 kg of cement and this could be higher if using nano-silica [2-4] ]. Another possibility is that the amount of cement remains the same and adds NS to improve the properties of concrete based on the special properties of NS [5,6]. Nano-silica increases hydration reaction, works with Ca(OH)2, produces C-S-H to increase the mechanical properties of concrete. Concrete with nano-silica will be tighter with less Ca(OH)2 crystals. According to Quercia [7], NS added to mortar and concrete can have different effects. The cause of this influence is due to the very high surface area of NS and activates the precipitation of C-S-H gel. The acceleration of the hydration rate of cement with NS was reported by Quing, Lin, Senff et al.

The general principle for improving the performance of concrete is based on the highly improved pozzolanic reaction by ultrafine nano-silica particles. The pozzolanic reaction takes place in concrete between calcium hydroxide and silica or silica acid in the presence of water. The result of the reaction is the formation of calcium silicate hydrate.

Mời độc giả xem nội dung đầy đủ bài khoa học tại đây

Tag:

Bình luận

Thông báo

Bạn đã gửi thành công.